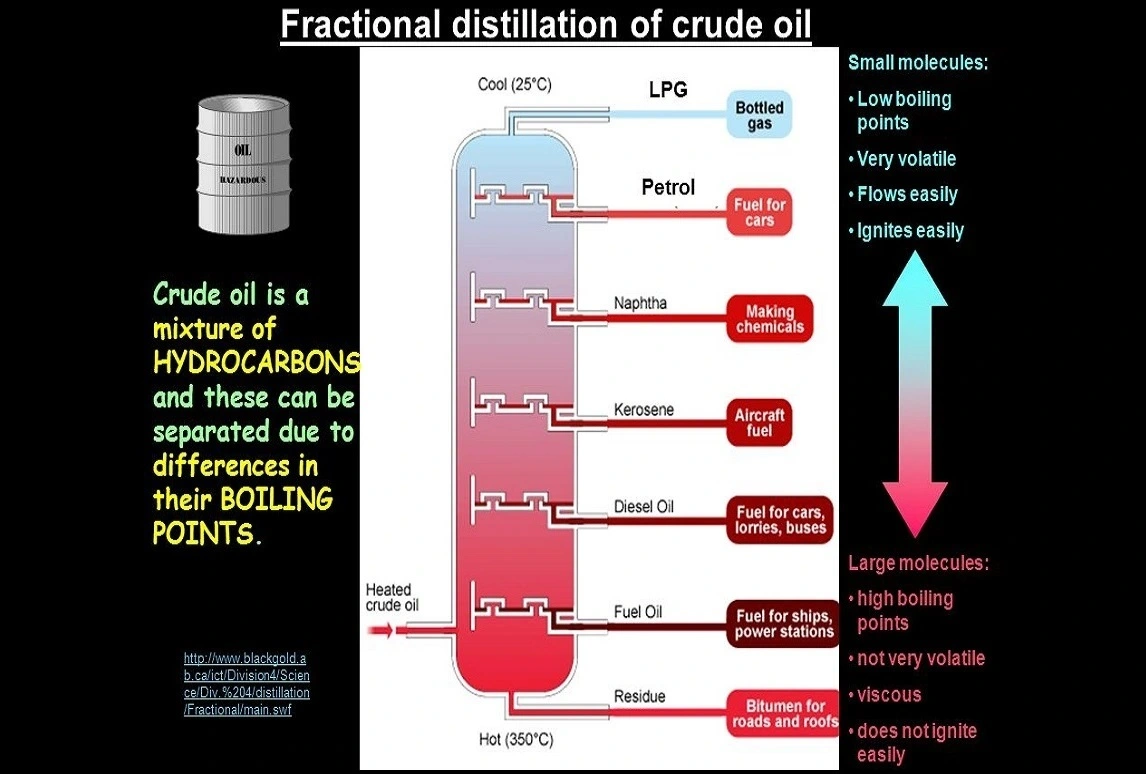

LPG Leakages, What causes this?

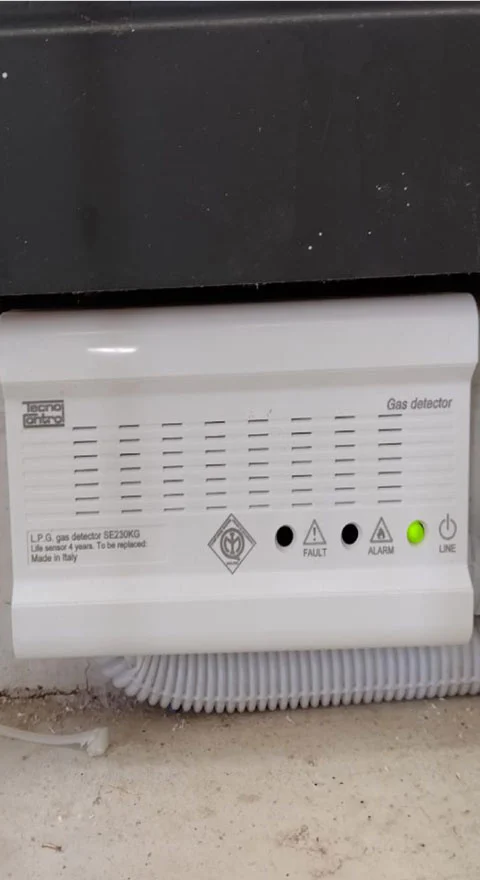

An LPG leak detector is a device that is designed to detect the presence of LPG gas in the air. It works by sensing the presence of the hydrocarbon compounds found in LPG and triggering an alarm when the level of LPG in the air exceeds a certain threshold.

There are different types of LPG leak detectors available on the market, each one uses a different technology to sense the presence of LPG.

- Electrochemical: These detectors use a sensor that detects the presence of LPG gas by measuring the concentration of the gas in the air. The sensor is typically a small cell that contains a chemical which reacts with LPG gas, producing an electric current that is proportional to the concentration of gas in the air. If the concentration of gas exceeds a preset limit, the detector will trigger an alarm.

- Catalytic bead: These detectors use a small bead coated with a substance that reacts with LPG gas to produce heat. When the heat generated exceeds a certain level, the detector triggers an alarm.

- Infrared: These detectors use infrared technology to detect the presence of LPG gas. They work by measuring the absorption of infrared light by LPG gas. A sensor in the detector detects the specific infrared signature of the LPG gas and triggers an alarm if the level exceeds a certain threshold.

- Ultrasonic: These detectors use sound waves to detect the presence of LPG gas. They work by measuring the reflection of sound waves off the LPG gas. An electronic sensor in the detector picks up the sound waves and triggers an alarm if the level exceeds a certain threshold.

LPG leak detectors are typically installed in the area where appliances are located, such as the kitchen, garage or basement. When a leak is detected, most detectors will trigger an audible alarm which alerts the user. They are an important safety feature that can help prevent fires and explosions by alerting you to the presence of LPG gas, giving you time to take action and prevent a potential incident.

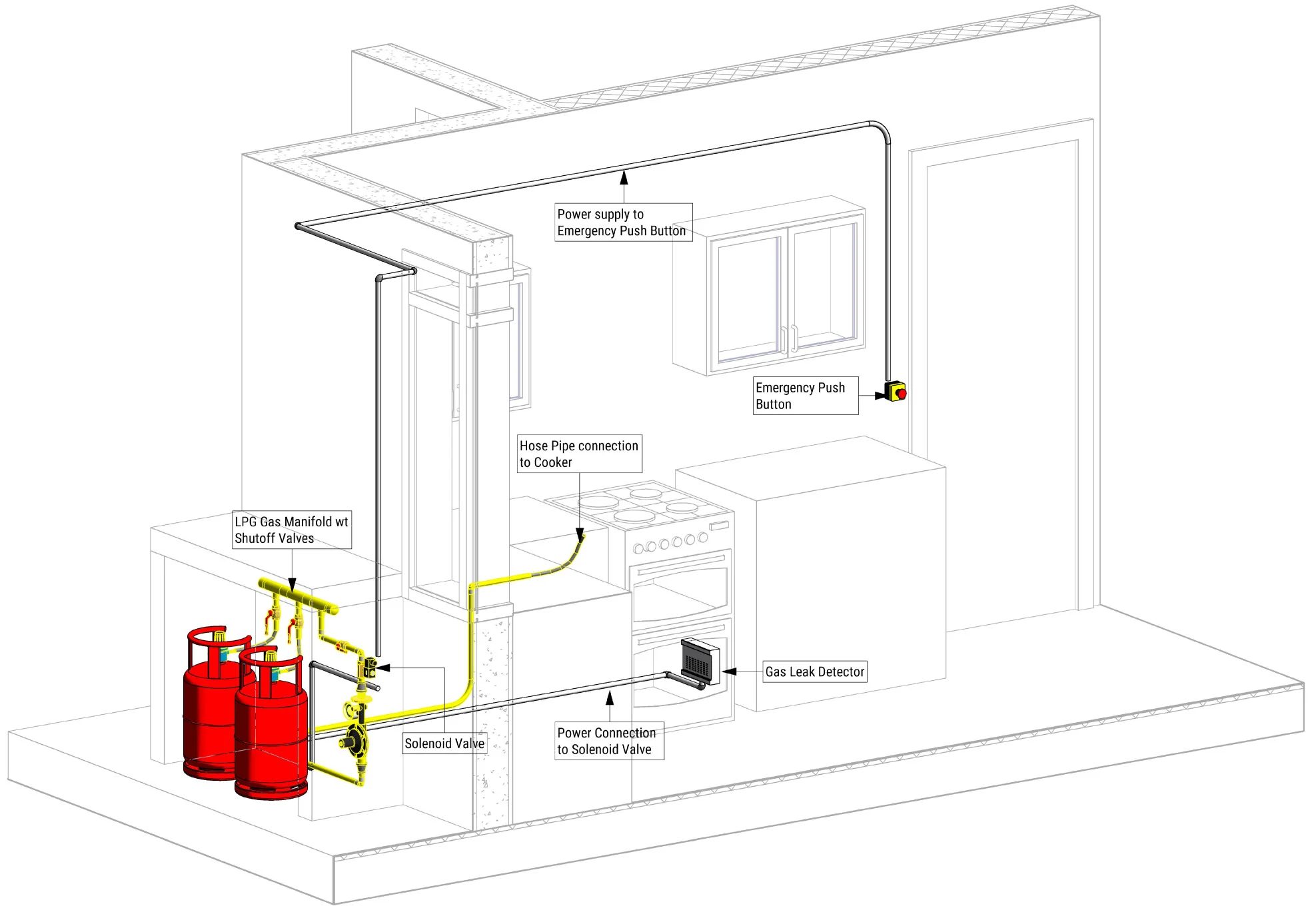

The Gas Leak Detection System

The Leak Detection Process

- When LPG leaks, it has a tendency to sink. The properties of LPG make it denser than air, causing it to sink.

- The Leak detector, which is usually located at low levels, will sense the presence of LPG as it sinks. The alarm within the detector will be activated as soon as a percentage threshold of LPG volume in relation to the air within the room, is reached.

- Activation of the alarm will result in immediate triggering of the solenoid valve, cutting of any further gas leaks from the LPG cylinders.

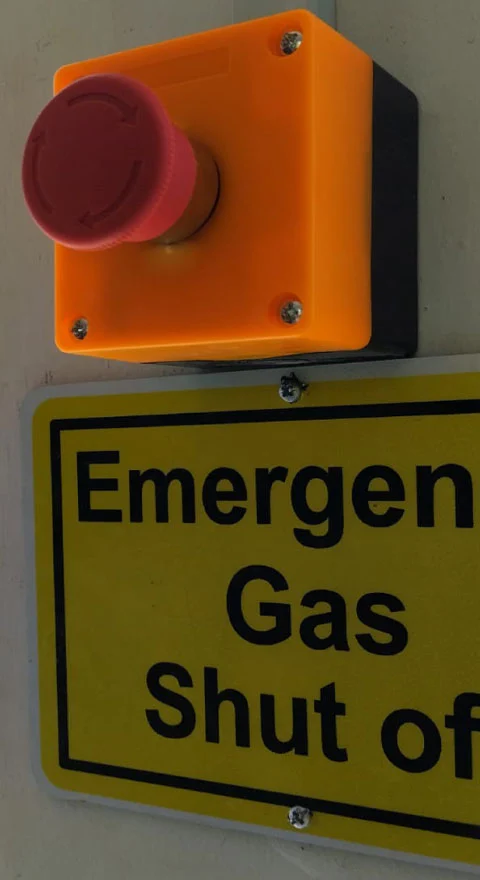

- In the event of a fire breakout, an emergency panic button that is installed at the nearest fire exit point, can be used to automatically cut-off gas supply using the same solenoid valve

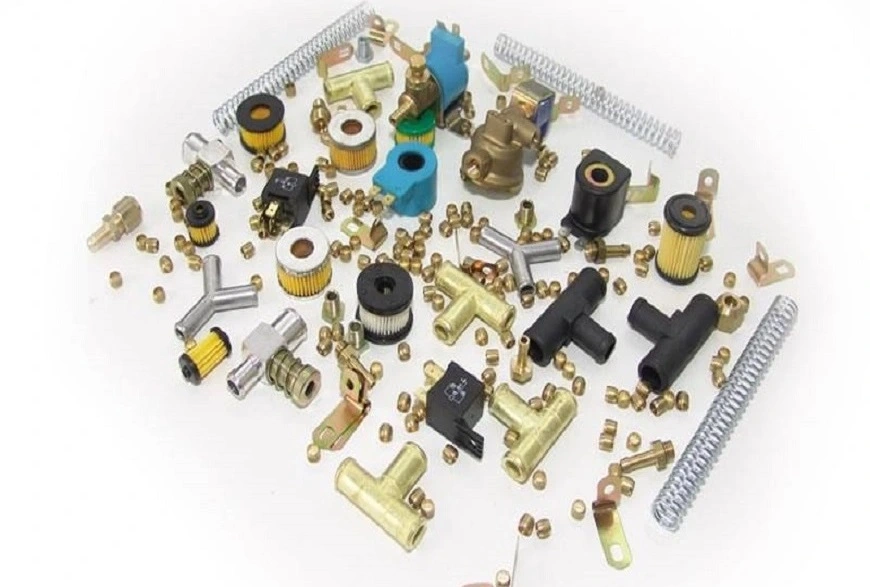

Components of the detection system

A gas leak detection system is designed to detect and alert when a gas leak occurs. The main components of a gas leak detection system typically include:

- Sensors: These are the devices that detect the presence of gas. They can be infrared, catalytic bead, or electrochemical sensors.

- Control panel: This is the hub of the system, it receives the signal from the sensors, process the signals and triggers an alarm if gas is detected.

- Alarm: An audible and/or visual alarm is activated when a gas leak is detected, it can be a siren, strobe light, or both.

- Power supply: The system needs a power supply to function, it can be AC or DC power.

- Communication devices: Some systems include communication devices such as GSM/GPRS modems or IP communication modules that allow the system to send alerts to remote locations or to a monitoring centre.

- Actuators: Some systems use actuators to automatically shut off the gas supply in case of leak detection.

- Calibration unit: This component is used to calibrate the sensors and ensure they are functioning properly.

- Maintenance and diagnostic tools: Some systems include tools to help with maintenance and troubleshooting.

- Remote monitoring and control: Some systems allow remote monitoring and control of the system through the use of software or mobile app.

It's important to note that there are different types of gas detection systems and not all of them will have all the components mentioned above, the specific components may vary depending on the type of gas, the environment, and the application.

How do you ensure that your Gas Leak Detection System is working properly?

There are several ways to ensure that a gas leak detection system is working properly:

- Regular inspections and maintenance: It is important to schedule regular inspections and maintenance for the gas detection system. This includes checking the sensors for proper function, replacing any damaged or worn parts, and ensuring that the alarms are working properly.

- Sensor calibration: Sensors need to be calibrated on a regular basis to ensure they are detecting gas accurately. Calibration can be done with a gas mixture or a gas generator that simulates a gas leak.

- Test alarms: Test the alarms regularly to ensure they are working properly. This can be done by activating the alarm manually or by simulating a gas leak with a gas mixture.

- Record keeping: Keep records of all inspections, maintenance, and calibrations. This can help to identify any problems and ensure that the system is operating at peak performance.

- Remote monitoring: Some systems allow remote monitoring of the system through the use of software or mobile app. This can help to detect any problems early on and allows for quick response and repair.

- False alarms: False alarms can be caused by a variety of factors, such as dust, humidity, or other environmental factors. These factors can be reduced by proper maintenance and cleaning of the sensors and the surrounding areas.

It's important to note that gas detection systems should be installed, maintained and serviced by a qualified and experienced technician or company following the manufacturer's instruction and local regulations.